The construction of a split cane rod requires many different work steps. Depending on the execution, up to 100 work hours or more are necessary. The following pictures will give you a small idea of the creation of such a rod.

-

Splitting the culm in halves

Splitting the culm in halves -

Flattening the nodes

Flattening the nodes -

Flaming the halves

Flaming the halves -

Splitting the strips

Splitting the strips -

Staggering the nodes

Staggering the nodes -

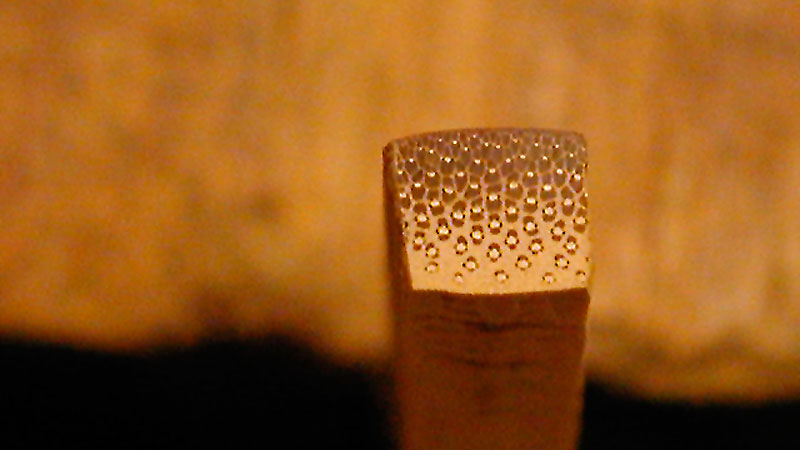

Detail of the power fibers

Detail of the power fibers -

Straightening the strips

Straightening the strips -

Complete shaped node (below)

Complete shaped node (below) -

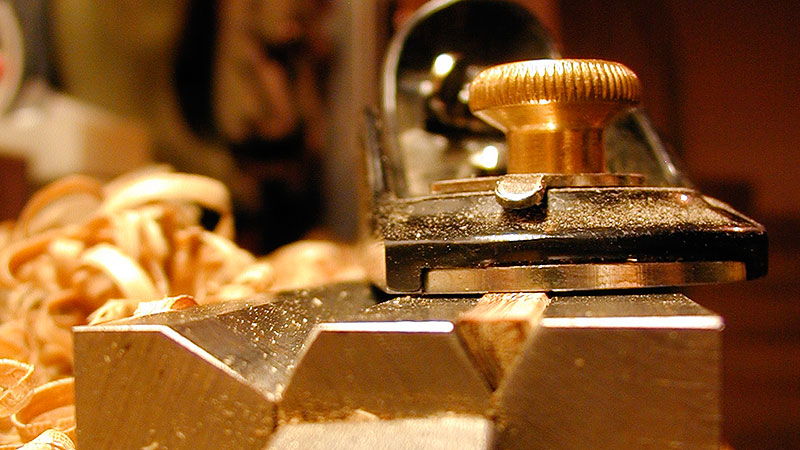

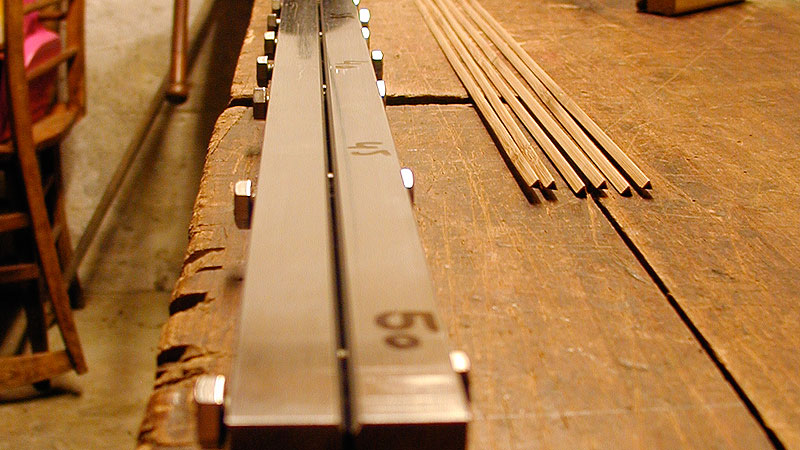

Rough planing

Rough planing -

Checking the angle

Checking the angle -

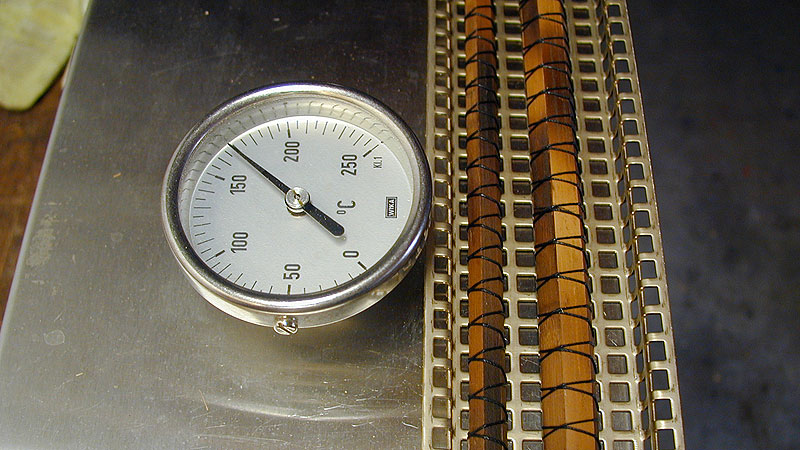

Heat-Treating the srips

Heat-Treating the srips -

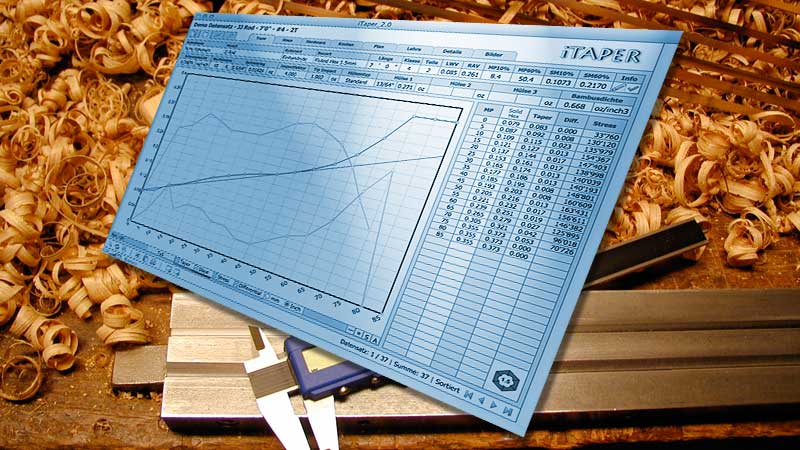

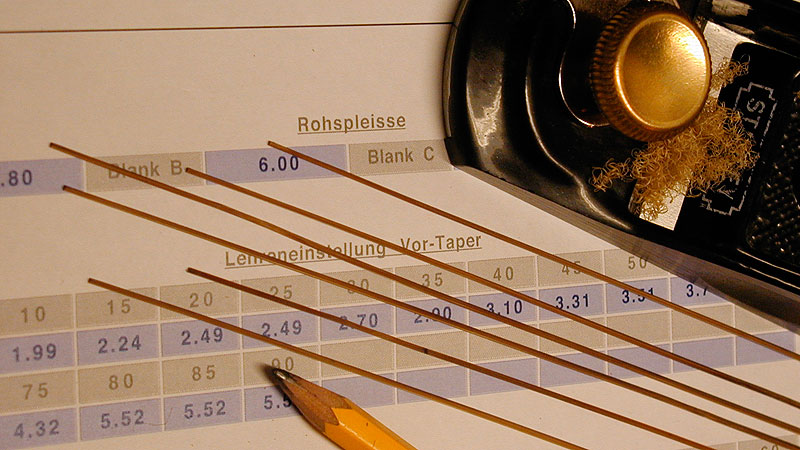

Planing the taper

Planing the taper -

Strips for the tip

Strips for the tip -

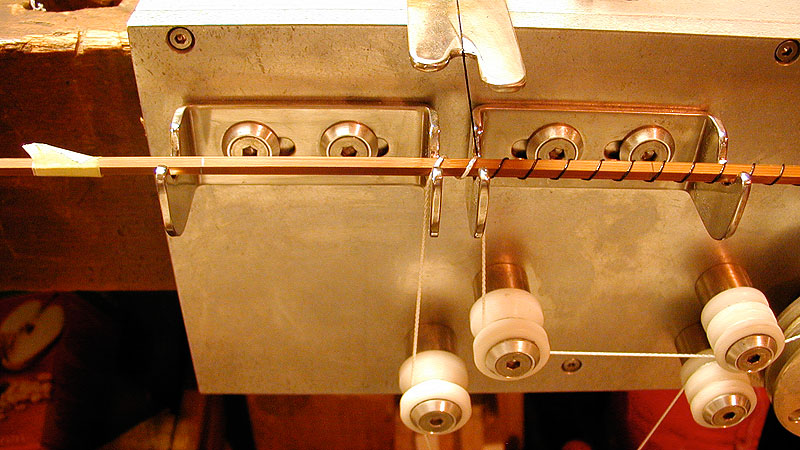

Gluing and binding the rod sections

Gluing and binding the rod sections -

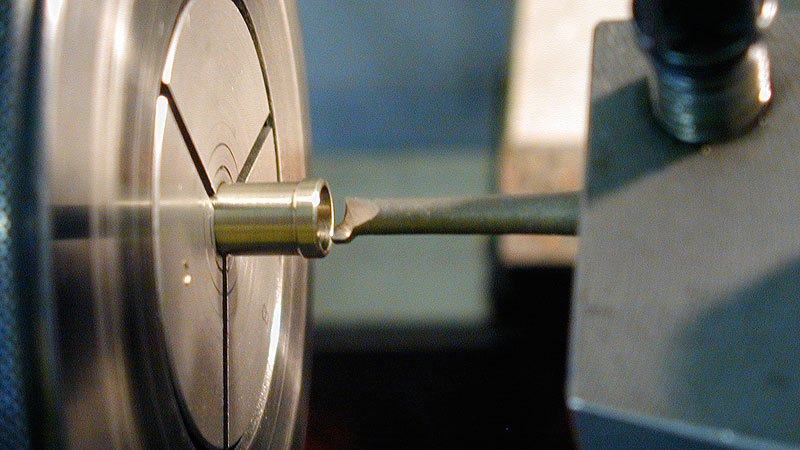

Turning the ferrule

Turning the ferrule -

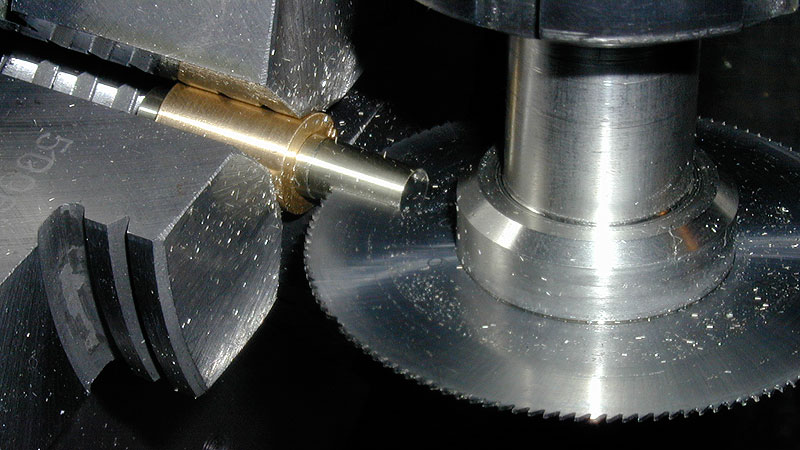

Milling the serrations

Milling the serrations -

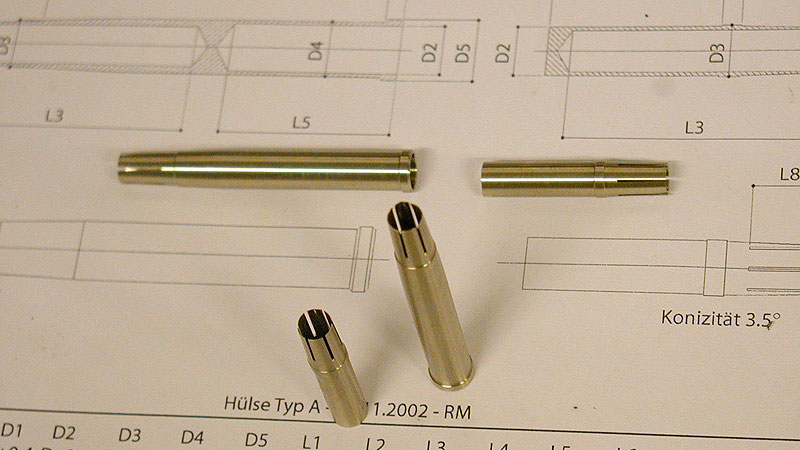

Nickel silver ferrule

Nickel silver ferrule -

Elaborate the crown

Elaborate the crown -

Complete mounted ferrule

Complete mounted ferrule -

Parts for the reel seat

Parts for the reel seat -

Mounting the reel seat

Mounting the reel seat -

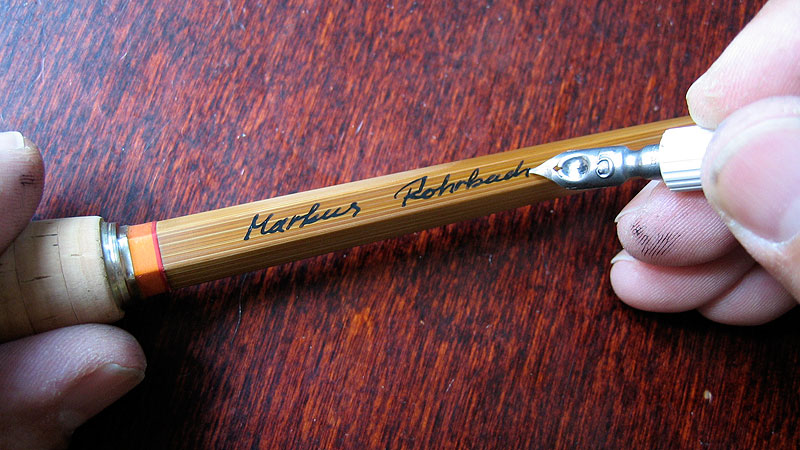

Signing the work

Signing the work -

Dip-Tube varnishing

Dip-Tube varnishing -

Guides ready for mounting

Guides ready for mounting -

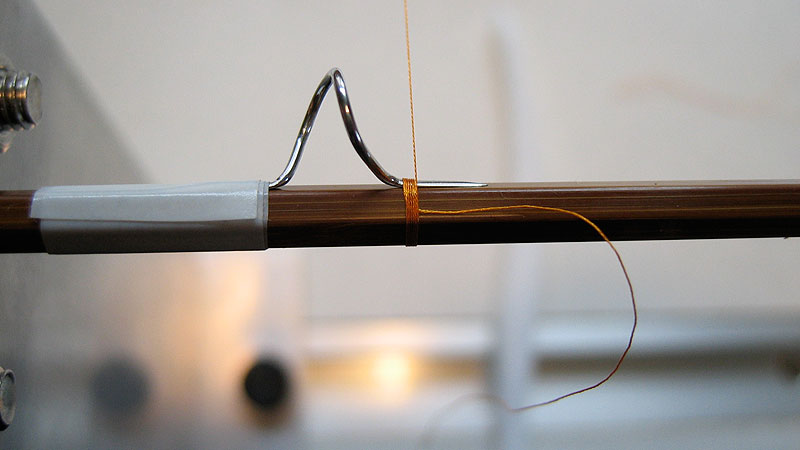

Guide mounting

Guide mounting -

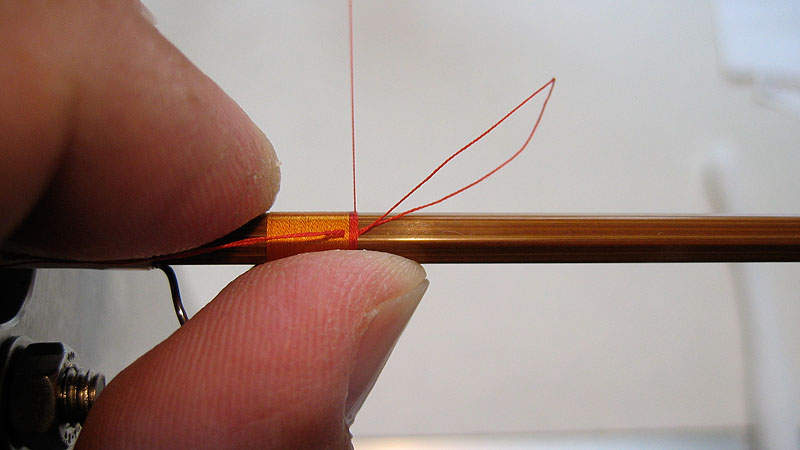

Tipping the wrap

Tipping the wrap -

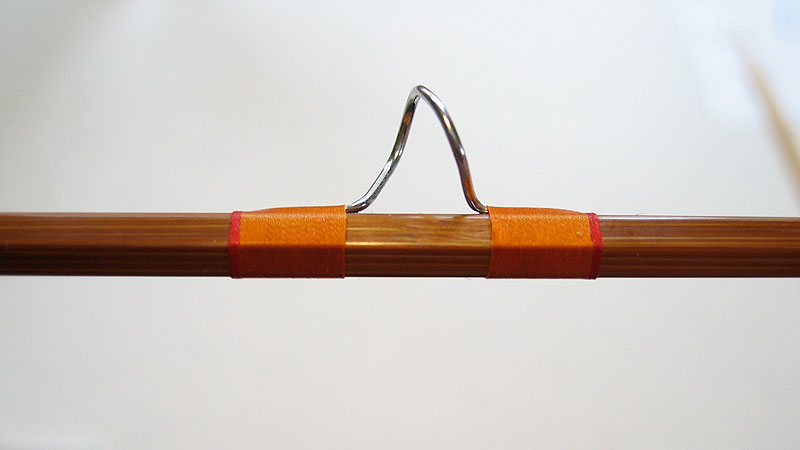

Complete mounted guide

Complete mounted guide -

Finished - Ready for fishing!

Finished - Ready for fishing!

English

English  Deutsch

Deutsch